Description

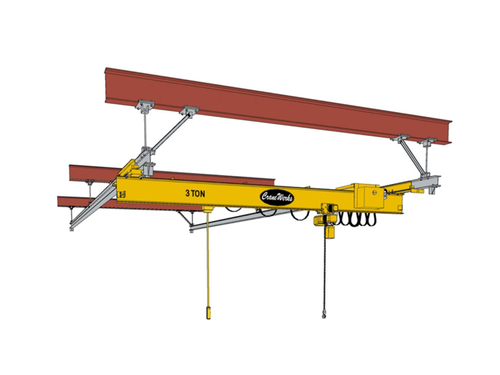

Generally a lot lighter than a top running system, under hung crane runways allows for more versatility. Underhung bridge cranes are typically used for lighter applications; under 20 tons. These systems can be mounted from the ceiling or interlocked together. Because the bridge runs underneath the runway rail, multiple systems can be ran side-by-side without interfering with one another. These overhead bridge cranes are ruggedly designed CMAA class C duty units (lighter and heaver duty cranes are available) see CMAA crane classification information to determine which class crane best fits your needs. CraneWerks bridge cranes are equipped with standard features that are optional on competitors’ cranes. Some options that may be included electronic soft start, side guide rollers on bridge crane end trucks, variable and 2 speed controls, free traveling pendant station and rubber bridge crane bumpers.

Capacities: up to 15 tons

Bridge Span Lengths, overall: up to 50' standard (available up to 100')

Runway Spans: determined by structure

Height — Floor-to-Trolley Clevis: determined by structure

Features:

- Use where speed requirements are 120 fpm per minute or less and where economy is important.

- Capacities of 1 to 15 ton

- All CraneWerks bridge cranes are available with radio controls and independent traveling pendants.

- CraneWerks pre-engineers many bridge cranes to allow for quick delivery.

- CraneWerks motorized bridge cranes are fully assembled and shop tested prior to shipping as one unit*

Applications:

- Equipment Assembly

- Die Handling

- Production

- Loading and Unloading

- Metal Grinding Cells

- Maintenance

- Suitable to run on I-beams, W-flanged beams and patented track runways

- Practically used in spans of 50 ft and less (Longer spans available up to 100 ft.) with the use of a third runway.

Design Details

Something unique to underhung cranes is their ability to be used in applications where the transfer of a loaded hoist and trolley from one beam to another beam is necessary. This can be accomplished through available transfer switches. With the use of these switches, ceiling mounted workstation bridge cranes can be utilized to transfer a load from one underhung crane to another underhung crane (from bay to bay), from a bridge to a single spur or to multiple monorail spurs and to transfer an unloaded hoist to a Hospital spur where it can be worked on and maintained with out interfering with critical plant operations. If two hospital spurs are used one can support a maintained hoist while the other can be empty ready to accept an ailing hoisting unit. This use of hospital spurs is a great way to keep a plant “in production”.

These underhung cranes are ruggedly designed CMAA class C duty units (lighter and heavier duty cranes are available) see CMAA crane classification information to determine which crane class best fits your needs.

Motorized bridge cranes commonly utilize electric chain hoists, underhung wire rope hoists,air hoists or balancers. All motorized overhead bridge cranes include either a tag line or c-track festoon system. Additional festoon systems are available when power or air supply is required for below the hook devices.

Reviews (0)

Be the first to review this product.

Additional Info

- SKU:

- RQ-CRAS-UHSGBC

- Availability:

- Call for Lead Time

- Standard Capacities:

- Up to 15 tons

- Spans:

- Up to 100 ft. (Bridge Length)

- Heights:

- Determined by structure

- Power Option:

- Yes

- Mounting:

- Underhung